Dehumidifying Dryer |

|

|

|

Dehumidifying dryer |

Name: Dehumidifying dryer Alias: Alias:Plastic Dehumidifying Dryer, Plastic dehumidification dryer, Plastic Dehumidifier, Plastic dryers,Resin dryers, Energy saving dehumidifying dryer Dehumidifying drying equipment. |

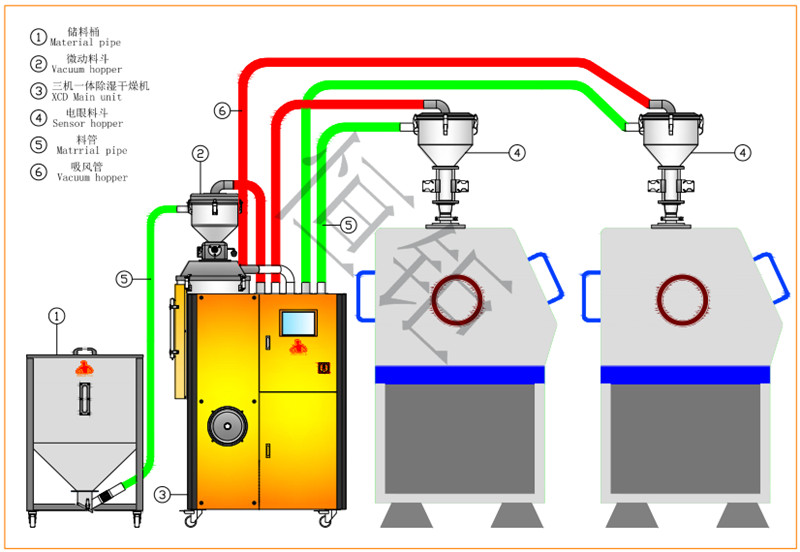

Dehumidifying dryer Introduction:Dehumidifying dryer is an automated equipment for drying plastic resin raw materials.Uses: Mainly used to produce plastic resin products. In the production of plastic or resin products, the moisture in the plastic or resin raw materials can be removed, and the problems of bubbles, silver streaks, cracks and poor product stability can be solved, and the product quality can be improved.For example: engineering plastics,Crystals,PET,PE pellets,PA,PBT,PC,plaststic granules and other raw materials. Working principle: The air duct of the dryer is a closed circulation system, and it is filtered at the same time. It is not affected by outsiders. The material can be dried in dry or humid weather without reversing the moisture, Energy saving and environmental protection,preventing dust from polluting the factory and improving the working environment, shortening the drying time and saving working time. It effectively improves the shortcomings of traditional hot air blowers. |

Dehumidifying dryer equipment |

Dehumidifying dryer application |

|

Plastic |

Dryer |

Density |

Drying time(h) |

Drying temperature |

Atmospheric flow(m3/kg) |

Moulding moisture content(%) |

Initial moisture content(%) |

| ABS | √ | 0.55 | 2-3 | 85 | 2 | <0.020 | <0.2 |

| CAB | √ | 0.60 | 2-3 | 70 | 2 | 0.020 | 0.6 |

| EVA(2) | √ | 0.60 | 2-3 | 90-105 | 1.8 | - | - |

| EVOH | √ | 0.60 | 2-3 | 90-105 | 2 | - | - |

| LM(4) | √ | 0.50 | 3 | 600 | 2 | 0.080 | <0.2 |

| LCP | √ | 0.80 | 3-4 | 150 | 2.2 | <0.01 | <0.05 |

| PA11 | √ | 0.60 | 3-5 | 70-80 | 2 | - | <0.6-1.2* |

| PA | √ | 0.83 | 6-8 | 180 | 1.23 | <0.03 | - |

| PA66 | 0.60 | 4-6 | 70-80 | 2 | <0.15-0.02* | <0.6-1.2* | |

| PAI | √ | 0.85 | 6-8 | 180 | 2 | <0.02 | - |

| PAR | √ | 0.70 | 5-6 | 120 | 2 | <0.02 | - |

| PBT | √ | 0.80 | 3-4 | 130-140 | 2.2 | <0.02 | <0.15 |

| PC | √ | 0.65 | 2-3 | 120 | 2 | <0.02 | <0.3 |

| PC/ABS | √ | 0.65 | 42798 | 100 | 2 | <0.020 | <0.1 |

| PC/PBT | √ | 0.75 | 3-4 | 110 | 2.2 | - | - |

| PE.HDEPE. LDPE black3% |

√ | 0.50 | 1 | 85 | 1.6 | <0.01 | <0.02 |

| PE.HDEPE. LDPE black40% |

√ | 0.70 | 2-3 | 80-90 | 2 | <0.02 | <0.2 |

| PEEK | √ | 0.80 | 3-4 | 150-160 | 2.2 | <0.05 | <00.1 |

| PE(1)(3) | √ | 0.75 | 4-5 | 140-160 | 2.5 | <0.01 | <0.2 |

| PEN(1)(3) | √ | 0.86 | 5-6 | 150-170 | 3 | <0.005 | - |

| PES | √ | 0.80 | 3-4 | 150-180 | 2 | <0.05 | <0.35 |

| PET | √ | 0.84 | 5-6 | 160-180 | 3 | <0.003 | <0.2 |

| PETG | √ | 0.74 | 4-5 | 65 | 3.5 | <0.01 | <0.1 |

| PI | √ | 0.70 | 2-3 | 120 | 2.2 | <0.02 | - |

| PMMA | √ | 0.65 | 3-4 | 80 | 3 | <0.02 | <0.3 |

| POM | √ | 0.85 | 2-3 | 90-100 | 2 | - | <0.15 |

| PP | √ | 0.50 | 1 | 80-90 | 2 | - | - |

| PPO | √ | 0.55 | 2 | 100-110 | 2 | <0.01 | - |

| PPS | √ | 0.80 | 2-3 | 130-140 | 2 | <0.01 | <0.03 |

| PS [GPPS.EPS.HIPS] |

√ | 0.55 | 1 | 80 | 1.7 | <0.02 | <0.05 |

| PSU | √ | 0.80 | 3-4 | 120-130 | 2 | <0.05 | <0.1 |

| PIT | √ | 0.80 | 5-6 | 130-150 | 3 | <0.05 | <0.2 |

| PUR | √ | 0.75 | 2-3 | 70-90 | 2 | 0.02 | - |

| PVC | √ | 0.85 | 1 | 70-80 | 1.4 | <0.02 | - |

| SAN | √ | 0.55 | 2-3 | 80 | 2 | <0.02 | <0.1 |

| SB | √ | 0.60 | 1-2 | 80 | 2 | <0.02 | - |

| TPE | √ | 0.65 | 2-3 | 110 | 2.2 | 0.05 | <0.3 |

| TPE | √ | 0.65 | 2-3 | 80 | 2.2 | <0.1 | - |

| TPO | √ | 0.55 | 3 | 70-90 | 2 | - | - |

| TPU | √ | 0.75 | 2-3 | 70-100 | 2 | <0.02 | - |

Working principle of plastic Dehumidifying dryer |

+8613669807274

+8613669807274