|

3 in 1 Dehumidifying dryer parameter

|

model |

Dehumidification air volume

CMH |

Dehumidification motor

KW |

Regenerative motor

KW |

Regenerative heater

KW |

Air inlet and outlet

INCH |

Voltage

PHASE |

Dimensions

MM |

|

DAD-50 |

50 |

0.37 |

0.18 |

2.0 |

2.0 |

220-380VAC

φ3.50HZ |

650(C)×600(W)×1100(H) |

|

DAD-80 |

80 |

0.55 |

0.18 |

2.7 |

2.0 |

690(L)×690(W)×1300(H) |

|

DAD-120 |

120 |

0.75 |

0.25 |

3.5 |

2.0 |

690(L)×690(W)×1300(H) |

|

DAD-150 |

150 |

1.1 |

0.37 |

4.5 |

2.5 |

765(L)×765(W)×1550(H) |

|

DAD-200 |

200 |

1.5 |

0.55 |

5 |

2.5 |

765(L)×765(W)×1550(H) |

|

DAD-300 |

300 |

2.2 |

0.75 |

7 |

3.0 |

900(L)×900(W)×1855(H) |

|

DAD-400 |

400 |

3.0 |

0.75 |

7 |

3.0 |

900(L)×900(W)×1855(H) |

|

DAD-500 |

500 |

3.8 |

1.1 |

10 |

4 |

1200(L)×1200(W)×2200(L) |

|

DAD-700 |

700 |

5.5 |

1.5 |

10 |

4 |

1200(L)×1200(W)×2200(L) |

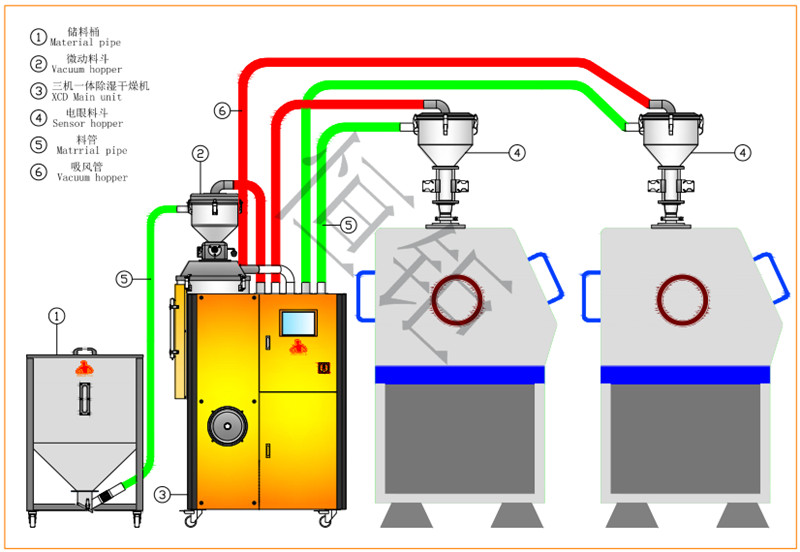

The composition of the 3 in 1 Dehumidifying dryer:

name |

Detailed introduction |

dehumidifier |

dehumidifier It is the main part of the three-machine integrated dehumidification dryer to automatically dehumidify the material to achieve drying

1. It adopts touch-sensitive human-machine interface, internally adopts PLC as main control, simple operation and stable operation;

2. Imported dehumidification wheel is adopted, with long service life;

3. Various temperature and conveying parameters can be set on the touch screen, which is flexible and convenient;

4. Various alarms are displayed on the touch screen, easy to monitor, safe and reliable;

5. With delayed start and stop functions, it can better protect the electric heater and motor. |

Drying hopper |

Drying hopper It is the main part of the material storage and supply of the three-in-one dehumidification dryer

1. The barrel body is made of SUS202 stainless steel, and the interior is ground and polished to avoid dust generation due to friction at dead corners;

2. Install an evacuation device at the bottom of the barrel to prevent residual material in the pipeline;

3. The double-layer barrel design saves energy;

4. The downward blowing design makes the temperature more uniform, and the blanking and heat dissipation are more balanced;

5. The cleaning door is designed to facilitate cleaning. |

Suction machine |

Suction machine It is the main part of the automatic feeding of the three-in-one dehumidification dryer

1. High-pressure closed motor is adopted, with strong conveying capacity and stable production;

2, using microcomputer control system, easy to control;

3. Equipped with an alarm device, when material shortage or failure occurs, an alarm will be issued to ensure that the equipment can operate normally. |

3 in 1 Dehumidifying dryer,Dehumidifying dryer,Dehumidifier dryers,plastic dryer,resin dryer |

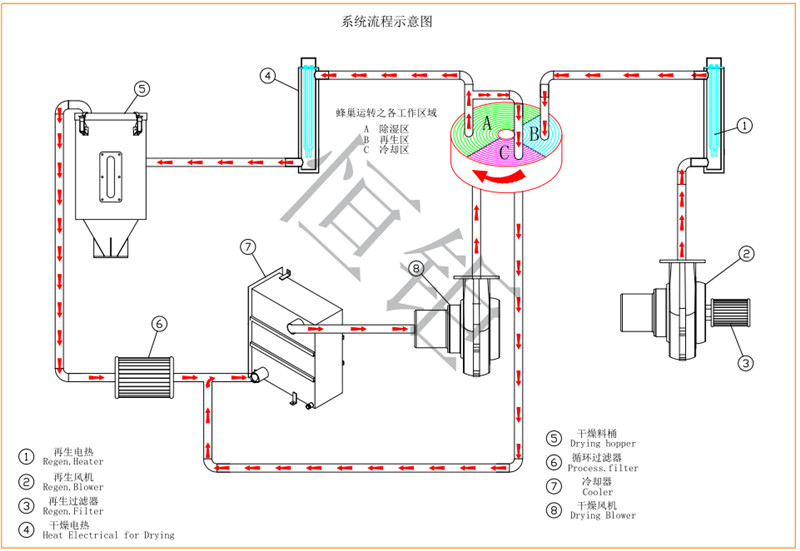

3 in 1 Dehumidifying dryer Equipment principle

1. The internal circulation of the dehumidifier: through the operation of the compressor → discharge high-temperature and high-pressure gas through the exhaust port → enter the condenser for cooling → become a low-temperature and high-pressure gas → intercept the flow through the capillary tube → become a low-temperature and low-pressure liquid → evaporate and absorb through the evaporator Heat → return to the compressor to become a low temperature and low pressure gas. This cycle is repeated.

2. The external circulation of the dehumidifier: under normal startup → through the operation of the fan → inhalation of moist air from the air inlet → through the evaporator → the evaporator absorbs the moisture in the air on the aluminum sheet → becomes dry air → Pass through the condenser to dissipate heat → blow out from the air outlet.

Product alias:3 in 1 Dehumidifying dryer, 3 in 1 Dehumidifying,3 in 1 dryer, |

3 in 1 Dehumidifying dryerapplication

In the plastics processing industry, the products appear shrinkage, silver streaks, bubbles, cracks, flow marks, poor transparency, etc. The main reason for these poor quality is that the plastics are not fully dried before they are formed. Engineering plastics such as : PA, PET, PU, TPU, PC, PBT, CA, PLA, TEP, resin and other highly hygroscopic raw materials, due to the penetration of water into the plastic particles, the traditional hot air dryer can not make it completely dry. Practice has proved that reducing the dew point of the drying wind to below -40°C while controlling the heat to blow it over the surface of the moisture-containing plastic particles can reduce its moisture content to below 0.02% before molding. The three-in-one dehumidification dryer is airtight. The circulatory system fully dehumidifies and heats the air, and the dry air quickly completely separates the moisture in the plastic particles to achieve the effect of dehumidification and drying.

No cooling water is required, so it is easy to move. The structure is simple and the machine has high reliability. The whole machine adopts microcomputer control, simple operation, stable performance, lower energy consumption, and the drying air volume is 30~2000m3/hr. In addition, the optical-grade energy-saving three-in-one dehumidification dryer is designed for the production of optical-grade products to meet the different needs of customers.

Features of three-in-one dehumidification dryer

1. High degree of automation reduces the labor intensity of operators;

2. The honeycomb runner using Japanese ceramic fiber as the base material has good dehumidification effect and stable and reliable performance;

3. It integrates three functions of dehumidification, drying and suction;

4. The feeding system is equipped with a shutoff valve to ensure that there is no residual raw material in the material pipe.

5. PID control of drying temperature and regeneration temperature;

6. PLC touch screen can be added, the operation is simple and clear at a glance;

7. Various complete protection circuits with dehumidification function after shutdown.

8. This series of dehumidification series adopts double cooler structure to ensure lower return air temperature and dew point.

Product alias:3 in 1 Dehumidifying dryer,Dehumidifying dryer,Dehumidifier dryers,plastic dryer,resin dryer |

3 in 1 Dehumidifying-dryer Precautions

Points for attention when using the three-in-one dehumidification dryer:

1. The desiccant dryer should be cleaned frequently and kept clean. The dehumidifier should be placed in the center of the room. The air inlet and outlet of the refrigerated dryer should not be blocked by obstructions, and the air filter should be cleaned. When the ambient temperature is lower than 15℃, the water droplets attached to the evaporator surface will freeze and the dehumidifier effect will be weakened. If the ambient temperature exceeds 40℃, the pressure in the system will increase and the compressor will overload. At this time, the overload protector The circuit should be cut off, otherwise the compressor motor will be damaged. So the best temperature range for dehumidifier is 15℃~40℃. If the humidity in the air is below 30%, it will be too dry and uncomfortable, so a reliable humidity controller will control it to maintain the range of 50% to 60%. When in use, close doors and windows as much as possible to achieve dehumidification in the room. The body of the desiccant dryer must be placed flat, not tilted or turned sideways, to avoid machine failure or abnormal noise.

2. The water storage in the desiccant dryer is too full. In order to avoid overflowing and contaminating the ground, when the machine body must be moved during operation, please unplug the power cord first, and then pour out the water in the water storage bucket. After moving the dehumidifier, it is best to put it statically for four to six hours before starting to use it. Because the compressor pipeline in the dehumidifier contains cold coal, it must take four to six hours to return the cold coal to its original position after being moved.

3. Clean the air filter regularly (about once every two weeks) to maintain the dehumidification and dust removal efficiency and life of the machine. Clean the air filter and wash it with water below 40°C; it is better to clean it with detergent. After washing off the dust, rinse it with water, dry it in the shade and put it back into the body. When cleaning the body, wipe it gently with a damp cloth; avoid directly splashing water for cleaning, so as not to damage the electrical insulation. Adhesives on the surface of the body can be cleaned with soap and water. Avoid spraying with gasoline, petroleum spirit, solvent or spray insecticide to avoid peeling paint or discoloration. Do not use thin rods or iron wires to dig out the inside of the machine to avoid malfunction or danger. Please unplug the power cord to maintain the life of the machine when it is out of power, not used for a long time, or when traveling.

Product alias:3 in 1 Dehumidifying dryer,Dehumidifying dryer,Dehumidifier dryers,plastic dryer,resin dryer |

|