|

|

Technology |

principle |

Video |

|

Accessories |

Industry Application |

Cost budget |

|

Equipment |

maintenance |

About us |

|

|

|

plastic Dehumidifying dryer |

dryer for plastic resin

Alias:

Resin dryer

Resin dehumidifier

Plastic dryer |

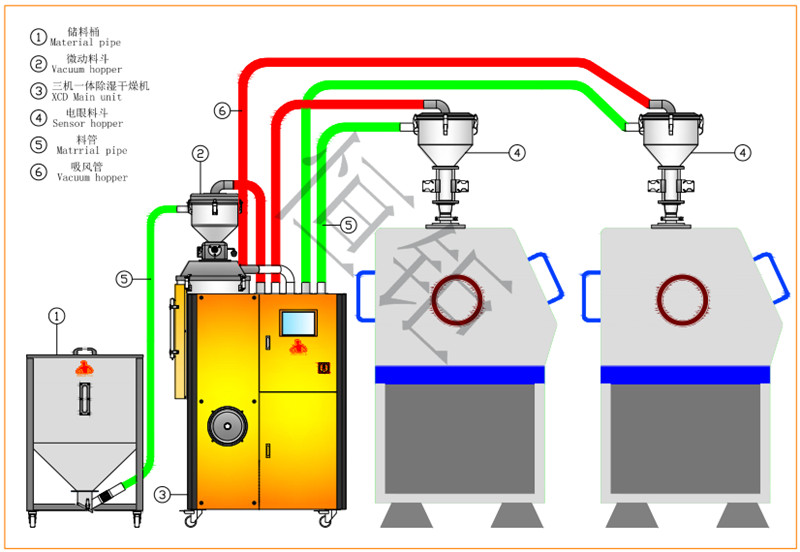

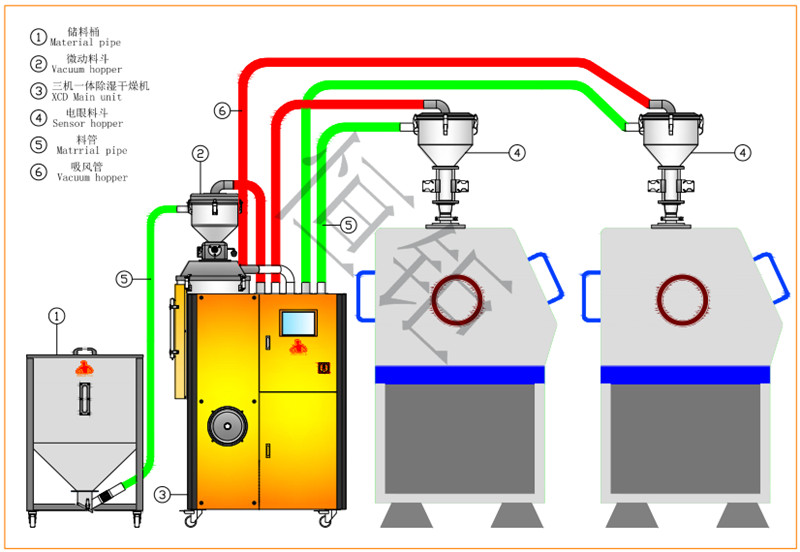

In the plastics processing industry, products appear shrinkage, silver streaks, bubbles, cracks, flow marks, poor transparency, etc. The main reason for these poor quality is that the plastics are not sufficiently dried before they are formed. Engineering plastics such as :Resin PA, PET, PC, PBT, CA and other materials with strong hygroscopicity, due to the penetration of water into the plastic particles, the traditional hot air dryer can not make it completely dry. Practice has proved that reducing the dew point of the drying wind to below -40°C while controlling the heat to blow it over the surface of the moisture-containing plastic particles can reduce its moisture content to below 0.02% before molding. The three-in-one dehumidification dryer is airtight. The circulatory system fully dehumidifies and heats the air, and the dry air quickly completely separates the moisture in the plastic particles to achieve the effect of dehumidification and drying.

Each function can work independently or fully automatically. It is a highly automated, labor-saving and energy-saving equipment.

|

Industry Application of Central Feeding System |

| Injection molding central feeding system |

Medical equipment central feeding system |

Central feeding system for plastic processing |

|

|

|

| Blown film centralized feeding system |

Blow molding centralized feeding system |

Injection centralized feeding system |

|

|

|

| Extrusion central feeding system |

Chemical Central Feeding System |

Cleaning centralized feeding system |

|

|

|

Central feeding system design solution |

Working principle of plastic Dehumidifying dryer |

|

plastic Dehumidifying dryer equipment and accessories |

|

The central control system console is the brain of the central feeding system, displaying various settings, operations and operating status; automatic dust removal and dust collection central feeding host A, B alternately automatically switch and manually select materials to prevent errors; monitor each The raw materials used by the molding machine, suction, insufficient raw materials and various abnormal phenomena of the central host (motor). !

To view more product information, please click here-(Suction Machine) |

|

Dehumidifying dryer is an important component of the central feeding system, which dehumidifies and drys plastics (PC/PE/PET/PLA/PP, etc.) during the production process! There are a variety of styles, such as three-in-one, special-purpose, honeycomb, standard and common types!

To view more product information, please click here--(plastic Dehumidifying dryer) |

|

In the central feeding system, the multi-color masterbatch is automatically and accurately weighed, and the automatic mixing and matching are performed well to reduce the color error!

To view more product information, please click here--(gravimetric blender) |

|

In the central feeding system, the mixture is automatically and accurately weighed, the automatic mixing performance is good, and the color difference is reduced! more details!!

To view more product information, please click here--(suction machine) |

|

An important part of the central feeding system equipment is to accurately weigh single-color materials! Accurate to the particles!!

To view more product information, please click here--(suction machine) |

|

The branch station is an indispensable part of the central feeding system and is used to distribute materials evenly for multiple forming machines!

To view more product information, please click here--(suction machine) |

|

The conveying pipeline is the material distributed in the axial direction of the central feeding system and transported to each machine through this pipeline for processing!

To view more product information, please click here--(suction machine) |

|

High-pressure machines are essential mechanical equipment in the central feeding system! Automatic production conveyor control!

To view more product information, please click here--(suction machine) |

|

The vacuum cleaner is usually located at the terminal of the central paper feeding system (determined according to the design application solution), and the terminal is sucked in to speed up the supply of raw materials!

To view more product information, please click here--(suction machine) |

plastic Dehumidifying dryer technology and equipment |

| Central feeding system equipment |

Common problems of central feeding system |

| |

|

|