|

EVA(2) dehumidifying dryer parameter

EVA(2) dehumidifying dryer

|

Plastic

material |

Dryer |

Density

(kg/dm3) |

Drying time(h) |

Drying temperature

(℃) |

Atmospheric flow(m3/kg) |

Moulding moisture content(%) |

Initial moisture contnt(%) |

| EVA(2) |

√ |

0.60 |

2-3 |

90-105 |

1.8 |

- |

- |

|

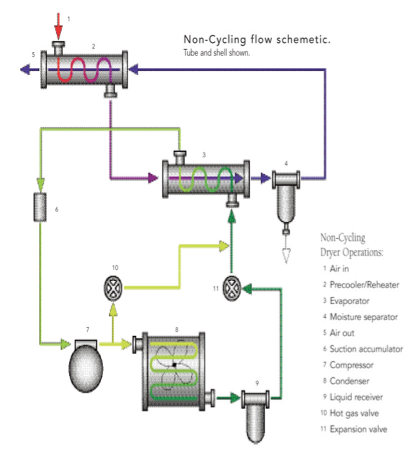

EVA(2) dehumidifying dryer Equipment principle

EVA(2) dehumidifying dryer

1. The internal circulation of the dehumidifier: through the operation of the compressor → discharge high-temperature and high-pressure gas through the exhaust port → enter the condenser for cooling → become a low-temperature and high-pressure gas → pass through the capillary tube → become a low-temperature and low-pressure liquid → evaporate and suck through the evaporator Heat → return to the compressor to become a low temperature and low pressure gas. So it goes back and forth.

2. The external circulation of the dehumidifier: under normal startup → through the operation of the fan → moist air is sucked in from the air inlet → passes through the evaporator → the evaporator absorbs the moisture in the air on the aluminum sheet → becomes dry air → Pass through the condenser to dissipate heat → blow out from the air outlet.

main feature:

1. The honeycomb runner made of ceramic fiber has good dehumidification effect;

2, PLC programmable touch screen can be equipped with more complete functions;

3. Ultra-low dew point temperature can be obtained. Ordinary cooling water can reach -40℃ dew point, and it can reach ultra-low dew point above -50℃ with chiller;

4. Dehumidification and regeneration work continuously in cycles to ensure stable dew point temperature, and the dew point is stable in a straight line below -40°C;

5. No pollution to ensure plastic quality;

6. The runner can withstand 1000℃ high temperature to prevent fire, acid and alkali, washable, and the average life span is more than 10 years;

7. The regeneration temperature is 180℃, which saves 2/3 time and 30-40% energy compared with traditional hot air dryers;

8. One dehumidifier can be used with several independent drying hoppers. can dry to a moisture content below 0.02%, and solves the shortcomings of poor transparency, sprue sticking, bubbles, silver bars, cracks, poor dimensional stability, internal stress, and insufficient product physical strength.

Dehumidification and drying feeding equipment series are composed of: non-heat dehumidification dryer, heat preservation type drying barrel and all stainless steel suction machine. The suction machine can transport the raw materials from the drying barrel to the forming machine, and can also transport the raw materials from the storage barrel to the drying barrel. According to customer needs, a kind of raw material can be delivered to two molding machines, vacuum motors and safety filter dust collectors are installed inside the machine. According to the production needs of different products, we can provide a powder-removing suction machine to separate the powder in the raw material and capture it. This device has a compact structure and is suitable for the production of precision injection products using engineering plastics such as connectors, precision gears, mobile phone communications, digital cameras and product size requirements, so that the moisture content of the raw materials after wet and dry is low and stable, which can meet strict requirements Technical and quality requirements.

Most engineering plastics are hygroscopic. When the plastic is taken out from the moisture-proof sealed packaging bag and exposed to the atmosphere, it will begin to absorb moisture from the atmosphere.

If it is a conventional hot-air barrel dryer, it is Humid external air can dry the plastic, so it cannot prevent the plastic from continuing to absorb moisture.

1. The internal circulation of the dehumidifier: through the operation of the compressor → discharge high-temperature and high-pressure gas through the exhaust port → enter the condenser for cooling → become a low-temperature and high-pressure gas → pass through the capillary tube → become a low-temperature and low-pressure liquid → evaporate and suck through the evaporator Heat → until the compressor becomes a low-temperature and low-pressure gas. So it goes back and forth.

2. The external circulation of the dehumidifier: under normal startup → through the operation of the fan → moist air is sucked in from the air inlet → passes through the evaporator → the evaporator absorbs the moisture in the air on the aluminum sheet → becomes dry air → Pass through the condenser to dissipate heat → blow out from the air outlet.

|

EVA(2) dehumidifying dryer application

EVA(2) dehumidifying dryer

1. Dehumidification at room temperature, pressure and humidity (T5 degrees Celsius -38 degrees Celsius; R45%~95%) Environment: generally adopt freezing dehumidification methods (the most primitive methods include wind blowing, sun exposure, fire roasting and lime).

2. Low temperature, normal pressure and normal humidity, low temperature, normal pressure and low humidity environment: generally use regenerative adsorption rotor to dehumidify.

3. High temperature, normal pressure, normal humidity and high temperature, normal pressure and low humidity environment: generally use a combination of water cooling and freezing (or wheel dehumidification).

Fourth, high-pressure air dehumidification and drying: generally use air dryer filters, special freeze dryers (cold dryers), or use dissolved drying towers.

The air pipeline of the desiccant dryer adopts a closed circulation system, which can not be affected by the external weather, and the material can be dried well in dry or humid days without reversing moisture. The filter installed in the desiccant dryer can prevent dust leakage from causing pollution in the factory and keep the air environment clean. With the widespread use of engineering plastics, Dehumidifying dryers have gradually replaced traditional hot air dryers.

This is a device used to dehumidifying plastic resin to achieve drying. For example,

POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),

PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,

PVC,SAN,SB,TPE,TPE,TPO,TPU,

Dehumidifier dryerand other plastic resins must be dehumidified and dried during the production process to improve the quality of the finished product.

EVA(2) dehumidifying dryer series are mainly designed for high-efficiency dehumidification of engineering plastics with strong hygroscopicity. Using the honeycomb runner with ceramic fiber as the base material, which represents the highest technological achievements of today, as the core component, the dry air provided can easily reach -40℃ dew point, and ideally it can reach -50℃ or even lower dew point , And the dew point temperature is stable, ensuring the high quality and stability of the molded plastic products. The whole series adopts P.LD. temperature control system as standard equipment; also provides PLC control with LCD touch-sensitive human-machine interface and can monitor the dehumidification effect of the machine Dew point meter is optional, the maximum drying air volume of this product can reach 3000m3/hr. The plastic before molding must be dried to an orientation ratio of less than 0.02%, which is completely bad, sprue adhesion, burrs, bubbles, silver bars, flow marks, cracks, dimensional stability and internal stress. Product defects (for example, insufficient physical properties and strength) are caused by sufficient dehumidification of the plastic before molding. Especially for PET, PBT, PA, PC and other high water absorption plastics, drying equipment with an ultra-low dew point of -40°C is required.

EVA(2) dehumidifying dryer series are mainly designed for high-efficiency dehumidification of engineering plastics with strong hygroscopicity. Using the honeycomb runner with ceramic fiber as the base material, which represents the highest technological achievements of today, as the core component, the dry air provided can easily reach -40℃ dew point, and ideally it can reach -50℃ or even lower dew point , And the dew point temperature is stable, ensuring the high quality and stability of the molded plastic products. The whole series adopts P.LD. temperature control system as standard equipment; also provides PLC control with LCD touch-sensitive human-machine interface and can monitor the dehumidification effect of the machine Dew point meter is optional, the maximum drying air volume of this product can reach 3000m3/hr. The plastic before molding must be dried to an orientation ratio of less than 0.02%, which is completely bad, sprue adhesion, burrs, bubbles, silver bars, flow marks, cracks, dimensional stability and internal stress. Product defects (for example, insufficient physical properties and strength) are caused by sufficient dehumidification of the plastic before molding. Especially for PET, PBT, PA, PC and other high water absorption plastics, drying equipment with an ultra-low dew point of -40°C is required.

EVA(2) dehumidifying dryer can be dried to a volume ratio of less than 0.02%, which solves the shortcomings of short circuit, gate adhesion, bubbles, silver bars, cracks, poor dimensional stability, internal stress and insufficient physical strength of the product. There are a lot more.

Mainly used in plastic products, automobiles, optical discs, experiments, communications, optics, etc.; the rotary honeycomb can reach a low dew point of zero bai for dehumidification and drying at -40°C. In the case of enhanced configuration, the dehumidification dew point can be as high as -50°C. It is a choice for high-precision industries.

EVA(2) dehumidifying dryer Precautions

EVA(2) dehumidifying dryer

Operation process of desiccant dryer:

1, please make sure the installation and adjustment have been completed;

2, please turn on the power switch of the control box and the dehumidifier panel;

3. When the temperature rises to the set temperature, check whether the temperature of the lower part is consistent;

4. The temperature indicator of the barrel can be inspected at any time, and the fault can be checked and repaired;

5. Keep the barrel full at any time during production;

6. When the raw materials are dried for a specified time, they can be produced;

7. Before stopping. First close the feeding plate and drain the raw materials underneath, then close the feeding system;

8. The standard temperature of the baking material is based on the following "plastic raw material baking temperature and time as the setting standard".

|

|

|