Dehumidifying Dryer |

|

|

|

Dehumidifying dryer |

Name: Dehumidifying dryer Alias: Alias:Plastic Dehumidifying Dryer, Plastic dehumidification dryer, Plastic Dehumidifier, plastic dryers, Energy-saving plastic dryer Plastic drying equipment. |

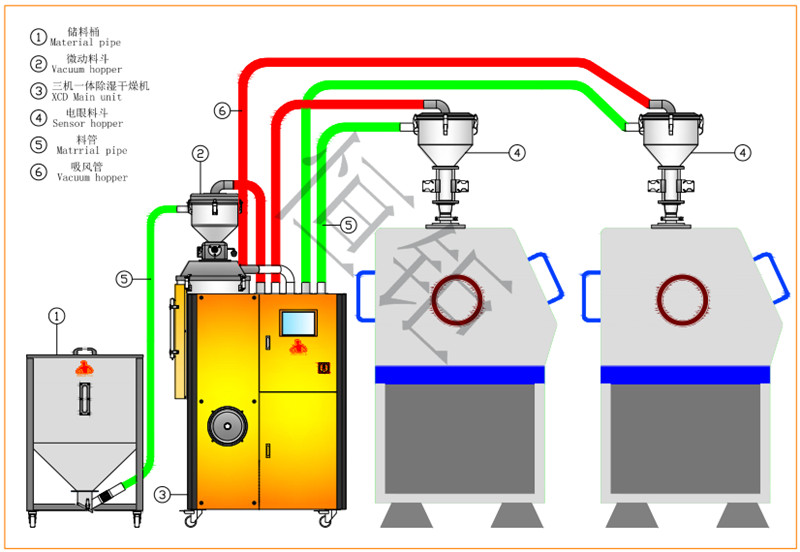

Dehumidifying dryer Introduction:Dehumidifying dryer Principle: The hot and humid air coming back from the drying barrel is cooled and blown into the honeycomb runner. The moisture in the air is adsorbed by the special runner, and then desorbed by the regenerated hot air. The two airflows act on the runner at the same time, and with the rotation of the runner, the moisture in the air is continuously adsorbed and desorbed by the regeneration air to be discharged, forming stable low dew point air, which is heated to The drying temperature of the plastic is blown into the drying barrel to form a closed cycle to dry the raw materials. Dehumidifying dryer Application: In the plastic (resin) molding process, bubbles, silver bars, poor transparency, cracks and poor stability are easy to produce. Dehumidifying dryers can dehumidify and dry plastics and resins (such as PA, PET, PC, PBT, etc.) to improve product quality! |

Dehumidifying dryer equipment |

Plastic/plastic dryer application |

General plastic parameters of dehumidifying dryer |

|

Plastic |

Dryer |

Density |

Drying time(h) |

Drying temperature |

Atmospheric flow(m3/kg) |

Moulding moisture content(%) |

Initial moisture contnt(%) |

| ABS | √ | 0.55 | 2-3 | 85 | 2 | <0.020 | <0.2 |

| CAB | √ | 0.60 | 2-3 | 70 | 2 | 0.020 | 0.6 |

| EVA(2) | √ | 0.60 | 2-3 | 90-105 | 1.8 | - | - |

| EVOH | √ | 0.60 | 2-3 | 90-105 | 2 | - | - |

| LM(4) | √ | 0.50 | 3 | 600 | 2 | 0.080 | <0.2 |

| LCP | √ | 0.80 | 3-4 | 150 | 2.2 | <0.01 | <0.05 |

| PA11 | √ | 0.60 | 3-5 | 70-80 | 2 | - | <0.6-1.2* |

| PA6.46.6 | 0.60 | 4-6 | 70-80 | 2 | <0.15-0.02* | <0.6-1.2* | |

| PAI | √ | 0.85 | 6-8 | 180 | 2 | <0.02 | - |

| PAR | √ | 0.70 | 5-6 | 120 | 2 | <0.02 | - |

| PBT | √ | 0.80 | 3-4 | 130-140 | 2.2 | <0.02 | <0.15 |

| PC | √ | 0.65 | 2-3 | 120 | 2 | <0.02 | <0.3 |

| PC/ABS | √ | 0.65 | 42798 | 100 | 2 | <0.020 | <0.1 |

| PC/PBT | √ | 0.75 | 3-4 | 110 | 2.2 | - | - |

| PE.HDEPE. LDPE black3% |

√ | 0.50 | 1 | 85 | 1.6 | <0.01 | <0.02 |

| PE.HDEPE. LDPE black40% |

√ | 0.70 | 2-3 | 80-90 | 2 | <0.02 | <0.2 |

| PEEK | √ | 0.80 | 3-4 | 150-160 | 2.2 | <0.05 | <00.1 |

| PE(1)(3) | √ | 0.75 | 4-5 | 140-160 | 2.5 | <0.01 | <0.2 |

| PEN(1)(3) | √ | 0.86 | 5-6 | 150-170 | 3 | <0.005 | - |

| PES | √ | 0.80 | 3-4 | 150-180 | 2 | <0.05 | <0.35 |

| PET | √ | 0.84 | 5-6 | 160-180 | 3 | <0.003 | <0.2 |

| PETG | √ | 0.74 | 4-5 | 65 | 3.5 | <0.01 | <0.1 |

| PI | √ | 0.70 | 2-3 | 120 | 2.2 | <0.02 | - |

| PMMA- | √ | 0.65 | 3-4 | 80 | 3 | <0.02 | <0.3 |

| POM | √ | 0.85 | 2-3 | 90-100 | 2 | - | <0.15 |

| PP | √ | 0.50 | 1 | 80-90 | 2 | - | - |

| PPO | √ | 0.55 | 2 | 100-110 | 2 | <0.01 | - |

| PPS | √ | 0.80 | 2-3 | 130-140 | 2 | <0.01 | <0.03 |

| PS [GPPS.EPS.HIPS] |

√ | 0.55 | 1 | 80 | 1.7 | <0.02 | <0.05 |

| PSU | √ | 0.80 | 3-4 | 120-130 | 2 | <0.05 | <0.1 |

| PIT | √ | 0.80 | 5-6 | 130-150 | 3 | <0.05 | <0.2 |

| PUR | √ | 0.75 | 2-3 | 70-90 | 2 | 0.02 | - |

| PVC | √ | 0.85 | 1 | 70-80 | 1.4 | <0.02 | - |

| SAN | √ | 0.55 | 2-3 | 80 | 2 | <0.02 | <0.1 |

| SB | √ | 0.60 | 1-2 | 80 | 2 | <0.02 | - |

| TPE | √ | 0.65 | 2-3 | 110 | 2.2 | 0.05 | <0.3 |

| TPE | √ | 0.65 | 2-3 | 80 | 2.2 | <0.1 | - |

| TPO | √ | 0.55 | 3 | 70-90 | 2 | - | - |

| TPU | √ | 0.75 | 2-3 | 70-100 | 2 | <0.02 | - |

Working principle of plastic Dehumidifying dryer |