Name: Plastic Dehumidifying Dryer Alias:Plastic dehumidification dryer, Alias:Plastic dehumidification dryer,

Plastic Dehumidifier,Plastic Dryer,

Plastic pellet dryer, Resin Dehumidifier, dehumidifying dryers |

Plastic Dehumidifying Dryer use:Dehumidifying dryers use very dry air for dehumidification;Shorten drying time and save working hours.

Before production, the moisture in the plastic or resin raw materials can be removed to solve the problems of bubbles, silver lines, cracks and poor product stability, and improve product quality.

The air duct of the dehumidifying dryer adopts a closed circulation system and is filtered at the same time. It is not affected by the outside climate. It can dry materials well in dry or humid weather without reversing moisture, thereby preventing dust from polluting the factory and improving the working environment.

It effectively improves the shortcomings of traditional hot air blowers. |

Plastic dehumidifying dryer composition:

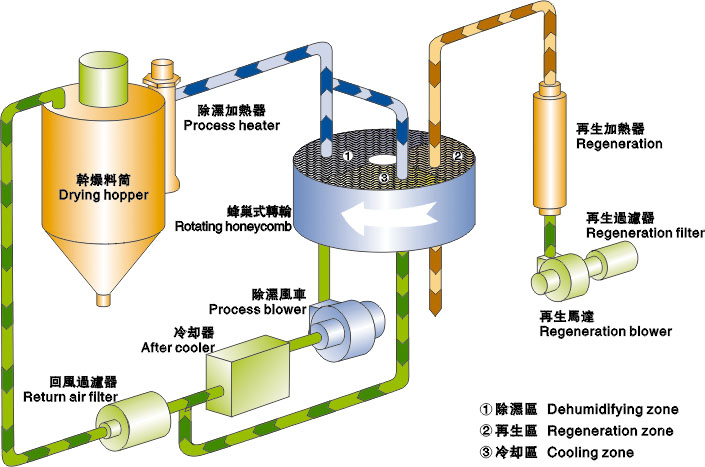

1. The two air streams act on the runner at the same time, and with the rotation of the runner, the moisture in the air is continuously adsorbed and desorbed by the regeneration air to be discharged, forming a stable low dew point air. It is heated to the drying temperature of the plastic and blown into the drying barrel to form a closed loop to dry the raw materials.

2. In the suction part, the suction is sucked into the dry bucket from the storage bucket or other storage bin containers. When the magnetic reed switch of the vacuum hopper detects that there is no material, the suction motor runs to make the vacuum hopper produce vacuum.

3. The raw materials in the storage tank are sucked into the vacuum hopper due to the pressure difference of the air. When the suction time is completed, the suction motor stops running, and the raw materials will fall into the drying tank due to their own weight. The material barrel is drawn into the electric eye hopper installed in the plastic molding machine.

4. The internal circulation of the dehumidifier: through the operation of the compressor → discharge high-temperature and high-pressure gas through the exhaust port → enter the condenser for cooling → become a low-temperature and high-pressure gas → intercept the flow through a capillary tube → become a low-temperature and low-pressure liquid → evaporate and suck through the evaporator Heat → return to the compressor to become a low temperature and low pressure gas. So it goes back and forth.

5. The external circulation of the dehumidifier: under normal startup → through the operation of the fan → moist air is sucked in from the air inlet → passes through the evaporator → the evaporator absorbs the moisture in the air on the aluminum sheet → becomes dry air → Pass through the condenser to dissipate heat → blow out from the air outlet.

honeycomb Rotor dryers, hopper dryers, crystal dryers, energy-saving dryers, three-in-one dryers

Plastic dehumidifying dryer use:If the plastic or resin is not dehumidified during the molding and processing of plastic or resin products, it is easy to produce bubbles, silver wires, cracks, and poor stability, which will affect product quality.

Mainly used for highly waterproof special plastics and resins, such as PET, PBT, PA, PC, etc. These resins require ultra-low dew point -40℃ dryer. The desiccant dryer integrates the three functions of dehumidification, drying, and two-stage feeding, and is especially suitable for engineering plastic materials with strong moisture absorption. Such as PA, PET, PC, PBT, etc., the optical grade GCD-OP model can be used to produce optical grade products, such as lenses, LCD light guide plates, optical discs, etc. Under ideal conditions, the lowest dew point can reach -40°C. .

Plastic dehumidifying dryer Reason for use: In the plastic processing industry, the products will have shrinkage, silver streaks, bubbles, cracks, melting, poor transparency and other problems. The main reason for this poor quality is that the plastic or resin raw materials are not completely dried before the product is molded. Industrial plastics such as PA, PET, PC, PBT, CA have high hygroscopicity. Because water enters the plastic particles, traditional hot air dryers cannot completely dry them. Practice has proved that reducing the dew point of the dry air below -40°C and controlling the heat blowing through the wet resin surface can reduce the moisture of the plastic particles. The moisture drops below 0.02%. When closing the mold. The circulation system of the desiccant dryer completely absorbs moisture and heats the air. The dry air quickly separates the moisture from the resin to achieve the effect of drying and dehumidification.

Plastic dehumidifying dryer working principle:

plastic pellet dryer,honeycomb Rotor dryers, hopper dryers, crystal dryers, energy-saving dryers, three-in-one dryersDrying unit: The hot and humid air in the drying barrel is cooled and blown into the honeycomb treadmill. The moisture in the air is absorbed by the treadmill and then deodorized by the regenerated hot air. The two airflows act on the slider at the same time, and as the flow channel rotates, the moisture in the air is continuously absorbed and absorbed by the regenerated air, thereby releasing free air. Stable low dew point, the heated plastic blows the drying temperature into the drying drum, forming a closed cycle to dry the material.

Suction part: Suction material is sucked from the barrel or other silo container into the dry barrel. When the magnetic switch of the vacuum hopper detects that there is no material, the suction motor operates to generate a vacuum in the vacuum hopper. The material in the barrel is sucked into the vacuum hopper due to the air pressure difference, the suction engine stops running at the end of this time, and the material falls into the drying barrel due to its own weight. The dried material is sucked from the drying barrel into the electric funnel installed in the injection molding machine

Plastic/plastic dryer application

Plastic dehumidifying dryer Features: 1. It integrates three functions of dehumidification, drying and feeding in two stages;

2. The dehumidifier is equipped with a roller device, which can provide stable air with low dew point, which can reach below -40℃;

3. The stainless steel double-layer thermal insulation drying box adopts the bottom blowpipe design to help the materials dry evenly and effectively prevent heat loss;

4. The feed system is equipped with a shut-off valve to ensure that there is no raw material in the feed pipe.

5. The closed-loop feeding system can prevent the raw materials from being contaminated or wetted;

6. The combination of optical grade GCD-OP type and electric boiling hopper can eliminate fine powder in raw materials and avoid pollution during the casting process of optical grade products.

7. The optical-grade GCD-OP sample system is equipped with high-precision and high-efficiency filters, which can efficiently filter dust ions up to 0.3μm, with a filtration rate of up to 99.9%. ;

8. You can purchase PLC control with LCD touch man-machine interface, centralized and convenient operation, and the whole machine can be controlled and run automatically;

9. You can buy a dew point detector;

Dehumidifying dryer equipment

Plastic dehumidifying dryer Relative humidity: honeycomb Rotor dryers, hopper dryers, crystal dryers, energy-saving dryers, three-in-one dryers

Relative humidity: At the same temperature, the percentage of actual water vapor density and saturated vapor density in the air is the relative humidity of the air.

|

Plastic

material |

Dryer |

Density

(kg/dm3) |

Drying time(h) |

Drying temperature

(℃) |

Atmospheric flow(m3/kg) |

Moulding moisture content(%) |

Initial moisture contnt(%) |

| ABS |

√ |

0.55 |

2-3 |

85 |

2 |

<0.020 |

<0.2 |

| CAB |

√ |

0.60 |

2-3 |

70 |

2 |

0.020 |

0.6 |

| EVA(2) |

√ |

0.60 |

2-3 |

90-105 |

1.8 |

- |

- |

| EVOH |

√ |

0.60 |

2-3 |

90-105 |

2 |

- |

- |

| LM(4) |

√ |

0.50 |

3 |

600 |

2 |

0.080 |

<0.2 |

| LCP |

√ |

0.80 |

3-4 |

150 |

2.2 |

<0.01 |

<0.05 |

| PA11 |

√ |

0.60 |

3-5 |

70-80 |

2 |

- |

<0.6-1.2* |

| PA6.46.6 |

|

0.60 |

4-6 |

70-80 |

2 |

<0.15-0.02* |

<0.6-1.2* |

| PAI |

√ |

0.85 |

6-8 |

180 |

2 |

<0.02 |

- |

| PAR |

√ |

0.70 |

5-6 |

120 |

2 |

<0.02 |

- |

| PBT |

√ |

0.80 |

3-4 |

130-140 |

2.2 |

<0.02 |

<0.15 |

| PC |

√ |

0.65 |

2-3 |

120 |

2 |

<0.02 |

<0.3 |

| PC/ABS |

√ |

0.65 |

42798 |

100 |

2 |

<0.020 |

<0.1 |

| PC/PBT |

√ |

0.75 |

3-4 |

110 |

2.2 |

- |

- |

PE.HDEPE.

LDPE black3% |

√ |

0.50 |

1 |

85 |

1.6 |

<0.01 |

<0.02 |

PE.HDEPE.

LDPE black40% |

√ |

0.70 |

2-3 |

80-90 |

2 |

<0.02 |

<0.2 |

| PEEK |

√ |

0.80 |

3-4 |

150-160 |

2.2 |

<0.05 |

<00.1 |

| PE(1)(3) |

√ |

0.75 |

4-5 |

140-160 |

2.5 |

<0.01 |

<0.2 |

| PEN(1)(3) |

√ |

0.86 |

5-6 |

150-170 |

3 |

<0.005 |

- |

| PES |

√ |

0.80 |

3-4 |

150-180 |

2 |

<0.05 |

<0.35 |

| PET |

√ |

0.84 |

5-6 |

160-180 |

3 |

<0.003 |

<0.2 |

| PETG |

√ |

0.74 |

4-5 |

65 |

3.5 |

<0.01 |

<0.1 |

| PI |

√ |

0.70 |

2-3 |

120 |

2.2 |

<0.02 |

- |

| PMMA- |

√ |

0.65 |

3-4 |

80 |

3 |

<0.02 |

<0.3 |

| POM |

√ |

0.85 |

2-3 |

90-100 |

2 |

- |

<0.15 |

| PP |

√ |

0.50 |

1 |

80-90 |

2 |

- |

- |

| PPO |

√ |

0.55 |

2 |

100-110 |

2 |

<0.01 |

- |

| PPS |

√ |

0.80 |

2-3 |

130-140 |

2 |

<0.01 |

<0.03 |

PS

[GPPS.EPS.HIPS] |

√ |

0.55 |

1 |

80 |

1.7 |

<0.02 |

<0.05 |

| PSU |

√ |

0.80 |

3-4 |

120-130 |

2 |

<0.05 |

<0.1 |

| PIT |

√ |

0.80 |

5-6 |

130-150 |

3 |

<0.05 |

<0.2 |

| PUR |

√ |

0.75 |

2-3 |

70-90 |

2 |

0.02 |

- |

| PVC |

√ |

0.85 |

1 |

70-80 |

1.4 |

<0.02 |

- |

| SAN |

√ |

0.55 |

2-3 |

80 |

2 |

<0.02 |

<0.1 |

| SB |

√ |

0.60 |

1-2 |

80 |

2 |

<0.02 |

- |

| TPE |

√ |

0.65 |

2-3 |

110 |

2.2 |

0.05 |

<0.3 |

| TPE |

√ |

0.65 |

2-3 |

80 |

2.2 |

<0.1 |

- |

| TPO |

√ |

0.55 |

3 |

70-90 |

2 |

- |

- |

| TPU |

√ |

0.75 |

2-3 |

70-100 |

2 |

<0.02 |

- |

Plastic dehumidifying dryer Dew point: Dew point: the temperature at which saturated water vapor condenses in the air. When the relative temperature is 100%, the ambient temperature is the dew point temperature. The dew point temperature is lower than the ambient temperature, and the lower the condensing capacity, which means that the drier the air, the greater the dew point is not affected by temperature, and the greater the pressure!

honeycomb Rotor dryers, hopper dryers, crystal dryers, energy-saving dryers, three-in-one dryers

Maintenance of plastic desiccant dryer/plastic pellet dryer,:(1) Ensure that the hot air is clean.

(2) Measures should be taken to prevent coke powder and avoid backflow of hot air.

(3) During the drying process of the material, all parts of the equipment in contact with the material must be cleaned and disinfected.

(4) For sticky materials, measures should be taken to minimize sticking.

(5) In order to improve the solubility, instant solubility, and dry products, they should be continuously discharged from the drying chamber quickly and packaged after cooling.

(6) The exhaust air temperature is allowed to exceed the requirements to ensure product quality and safety.

plastic pellet dryer,honeycomb Rotor dryers, hopper dryers, crystal dryers, energy-saving dryers, three-in-one dryers

|

+8613669807274

+8613669807274

+8613669807274

+8613669807274 wto-btb@wto-btb.com

wto-btb@wto-btb.com Tel: +8613669807274

Tel: +8613669807274 SMS: +8613669807274

SMS: +8613669807274