This is a desiccant dryer for PET materials. The PET dryer is a dehumidification and drying equipment for PET materials (including PET granules and pet powder materials). Solve the problems of bubbles, silver lines, cracks and poor stability of PET products during the production process!

Manufacturing method of continuous drying device for PET bottle flakes

[Patent Abstract] The present invention discloses a continuous drying device for PET bottle flakes that can continuously dry, greatly improve production capacity, and have low energy consumption. It includes a drying tower, a crystallizer and a silo. The bottom of the drying tower is provided with an outlet The feed port, the drying air inlet at the lower end of the drying tower is connected with a dry gas blowing mechanism, the silo is arranged above the crystallizer, and a valved feed is provided between the outlet of the silo and the inlet of the crystallizer The said crystallizer is arranged at the top of the drying tower, and the crystallizer is connected with the drying tower, the lower end of the crystallizer is provided with a crystallization gas inlet, and the top of the crystallizer is provided with a crystallization gas outlet from the crystallization gas outlet A cyclone separator, a dust remover, a crystallization fan, and a crystallization heater are sequentially arranged on the crystallization gas pipeline between the crystallization gas inlet.

[Patent Description] Continuous drying device for PET bottle flakes

【Technical Field】

The invention relates to a drying device for PET bottle flakes.

【Background technique】

At present, the drying process of PET bottle flakes requires two processes of crystallization in the crystallizer and drying in the drying tower. The traditional crystallizer and drying tower each form a working system and work independently of each other. The disadvantages are: complex structure, continuous drying, low production capacity.

[Content of the invention]

The technical problem to be solved by the present invention is to provide a continuous drying device for PET bottle flakes that can be continuously dried, the production capacity is greatly improved, and the energy consumption is low.

In order to solve the above problems, the technical solution adopted by the present invention is: a continuous drying device for PET bottle flakes, including: a drying tower, a crystallizer and a silo. The bottom of the drying tower is provided with a discharge port, and the drying air inlet at the lower end of the drying tower A dry gas blowing mechanism is connected, the silo is arranged above the crystallizer, a feed pipe with a valve is arranged between the outlet of the silo and the inlet of the crystallizer, and the crystallizer is arranged in the drying tower The top of the crystallizer is connected with the drying tower, the lower end of the crystallizer is provided with a crystallization gas inlet, the top of the crystallizer is provided with a crystallization gas outlet, and the crystallization gas pipeline between the crystallization gas outlet and the crystallization gas inlet A cyclone separator, a dust collector, a crystallization fan, and a crystallization heater are arranged on the top in sequence.

Further, in the aforementioned continuous drying device for PET bottle flakes, the structure of the dry gas blowing mechanism includes: a dry gas pipeline, on which an air compressor, a dehumidifier, and a drying heater are arranged in sequence. The air blown by the press passes through the dehumidifier and the drying heater in sequence, and then enters the drying tower from the drying air inlet.

The beneficial effects of the present invention: On the one hand, the PET bottle flakes in the silo continuously enter the crystallizer through the feed pipe for crystallization, and the crystallized PET bottle flakes enter the drying tower I for drying, and the PET bottle after the drying is completed The flakes are discharged from the discharge port at the bottom of the drying tower, so as to realize the continuous drying of PET bottle flakes; on the other hand, the crystallization gas adopts the air discharged from the drying tower and releases part of the heat, and continues to circulate, thereby greatly reducing The energy consumption in the drying process of PET bottle flakes reduces the drying cost of PET bottle flakes.

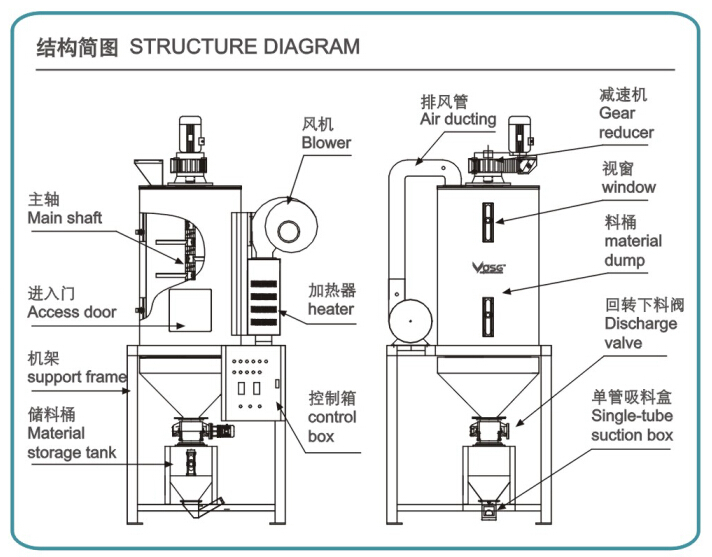

【Explanation of drawings】

It is a schematic diagram of the structure of the continuous drying device for PET bottle flakes according to the present invention.

【Detailed ways】

The present invention will be further described in detail below in conjunction with the best embodiment.

As shown, the continuous drying device for PET bottle flakes includes: a drying tower 1, a crystallizer 6, and a silo. The bottom of the drying tower I is provided with a discharge port, and the drying air inlet at the lower end of the drying tower I is connected with a drying gas blowing in Mechanism, its structure includes: dry gas pipeline, air compressor, dehumidifier, drying heater are arranged in order on the dry gas pipeline, the air blown by the air compressor passes through the dehumidifier and drying heater in turn and enters from the drying inlet Inside the drying tower I. The silo is arranged above the crystallizer. A feed pipe with a valve is arranged between the outlet of the silo 7 and the inlet of the crystallizer 6. The crystallizer is arranged on the top of the drying tower I and crystallizes. The crystallizer is connected with the drying tower I, the lower end of the crystallizer is provided with a crystallization gas inlet, the top of the crystallizer is provided with a crystallization gas outlet, and the crystallization gas pipeline from the crystallization gas outlet to the crystallization gas inlet is sequentially arranged Cyclone separator, dust collector

11. Crystal fan, crystal heater.

The working principle of the present invention is as follows: PET bottle flakes in the silo continuously enter the crystallizer 6 through the feed pipe 8 for crystallization, and the crystallized PET bottle flakes enter the drying tower I for drying, and the PET bottle after the drying is completed The flakes are discharged from the discharge port at the bottom of the drying tower I, thereby realizing the continuous drying of PET bottle flakes and improving the production capacity of PET bottle flake drying. During the drying process, air is continuously blown into the drying gas pipeline by an air compressor, and is sequentially dehumidified by the dehumidifier 4 and dried and heated by a drying heater to form high-temperature dry air. The high-temperature dry air enters the drying tower I and flows upwards, thereby drying the PET bottle flakes in the drying tower I, and the air that releases part of the heat enters the crystallizer to form crystals for the crystallization of the PET bottle flakes in the crystallizer The crystallization gas releases heat again in the crystallizer. After drying and crystallization, the heat-releasing gas is mixed with fine particles, and the gas mixed with fine particles enters the crystallization gas pipeline from the crystallization gas outlet, and then enters the cyclone separator to separate the fine particles. , The dust collector 11 further removes dust. The clean air after dust removal is transported to the crystallization heater for heating under the action of the crystallization fan. After the heating is completed, high-temperature air is formed and transported to the crystallizer again to form PET bottle flakes. The crystallization of the crystallization gas. The crystallization gas adopts the air discharged from the drying tower I, which releases part of the heat, and is continuously circulated, thereby greatly reducing the energy consumption in the drying process of the PET bottle flakes, thus reducing the drying cost of the PET bottle flakes.

【Rights request】

1. The continuous drying device for PET bottle flakes includes a drying tower, a crystallizer and a silo. The bottom of the drying tower is provided with a discharge port, and the drying air inlet at the lower end of the drying tower is connected with a drying gas blowing mechanism, which is characterized by : The silo is set above the crystallizer, a feed pipe with a valve is set between the outlet of the silo and the inlet of the crystallizer, the crystallizer is set on the top of the drying tower, and the crystallizer is connected to the The drying tower is connected, the lower end of the crystallizer is provided with a crystallization gas inlet, the top of the crystallizer is provided with a crystallization gas outlet, and the crystallization gas pipeline from the crystallization gas outlet to the crystallization gas inlet is sequentially provided with a cyclone separator , Dust collector, crystallization fan, crystallization heater.

2. The continuous drying device for PET bottle flakes according to claim 1, characterized in that: the structure of the dry gas blowing mechanism includes: a dry gas pipeline, and an air compressor and a dehumidifier are arranged in sequence on the dry gas pipeline , Drying heater, the air blown by the air compressor passes through the dehumidifier, the drying heater and then enters the drying tower from the drying air inlet.

|

+8613669807274

+8613669807274

+8613669807274

+8613669807274 wto-btb@wto-btb.com

wto-btb@wto-btb.com Tel: +8613669807274

Tel: +8613669807274 SMS: +8613669807274

SMS: +8613669807274