Gravimetric blender |

|

| product name:Gravimetic blender |

| release time:2020-12-23 13:57:45 |

| Numbering:Gravimetic blender-001 |

| Brand:HENGJU |

| Price:¥By function |

| weight :By function |

| unit weight:Kg/set |

| manufacturer:hengju |

| patent:hengju |

| Producing country: |

| simple description:TA gravimetic blender is an item of industrial equipment used in the plastics industry to accurately weigh two or more components and then mix them together prior to processing in an injection molding machine, plastics extrusion, or blow moulding machine. |

| Alias:Gravimetic blender,Plastic dosing unit,Gravimetic dosing system,Gravimetic batch blender, Batch blender,Weighing blender,Gravimetic dosing and mixing units |

|

|

What is Gravimetric blender A gravimetic blender is an item of industrial equipment used in the plastics industry to accurately weigh two or more components and then mix them together prior to processing in an injection molding machine, plastics extrusion, or blow moulding machine.

The gravimetic blender puts different materials in different hoppers. After the corresponding weight is set by the controller according to the specified ratio in advance, the corresponding unloading cylinder is activated to make the corresponding pull plate Open the discharge port of the hopper, the material will fall on the weighing device, and the weighing device will transmit the information to the controller after the weight of the weighed material reaches the set value. The controller receives the information and controls the corresponding unloading cylinder Action, make the corresponding pull plate close the discharge port of the hopper, the material will no longer fall, and realize the automatic feeding according to the preset weight ratio, saving time and effort;

The upgraded version of the new Gravimetric blender reduces the accuracy of the measurement error of each material of powder or granular materials to (±0.001) (with independent patent) |

|

Composition of gravimetic blender 1. Upper hopper, 2. Display, 3. Unloading cylinder, 4. Controller, 5. Mixing box, 6. Observation window, 7. Lower hopper, 8. Discharge valve, 9. Sub-hopper, 10. Motor, 11. Feeding port of sub-hopper, 12. Discharge port of sub-hopper, 13. Pull plate, 14. Cylinder assembly box, 15. Weighing hopper, 16. Horizontal screw, 17. Mixing hopper.

Schematic diagram of gravimetic blender |

Physical map of gravimetic blender |

|

|

Model of Gravimetic blender

standard type |

Upgraded version |

patent version |

|

|

|

| Model |

HGB-50 |

100 |

200 |

400 |

600 |

800 |

1200 |

2000 |

2500 |

3000 |

| Qty of group number |

4-8 |

| Mixing capacity(kg/hr) |

50 |

100 |

200 |

400 |

600 |

800 |

1200 |

2000 |

2500 |

3000 |

| Batch weight(kg) |

0.6 |

1.2 |

2.2 |

4.5 |

6 |

8 |

12 |

20 |

25 |

30 |

| Main material range(%) |

5-100 |

| Additive mixing range(%) |

0.5-10 |

| Main hopper volume(L) |

18 |

25 |

32 |

45 |

70 |

100 |

130 |

160 |

180 |

230 |

| Mixing barrel volume(L) |

6 |

6 |

20 |

20 |

40 |

40 |

80 |

80 |

100 |

180 |

| Power supply(v/hz) |

1φ |

1φ |

1φ |

1φ |

1φ |

1φ |

3φ |

3φ |

3φ |

3φ |

| |

230/50 |

230/50 |

230/50 |

230/50 |

230/50 |

230/50 |

400/50 |

400/50 |

400/50 |

400/50 |

| Total power(kw) |

0.12 |

0.12 |

0.25 |

0.25 |

0.55 |

0.55 |

1.5 |

1.5 |

1.5 |

3 |

| Compressed air(kgf/cm2) |

6-8 |

| Max noise level(dB) |

<75 |

|

|

|

Working principle of Gravimetic blender The Gravimetic blender includes an upper hopper 1, a mixing box 5, a lower hopper 7 and a controller 4 connected in sequence. The upper hopper is divided into a plurality of sub-hoppers 9 by a partition, each of which is The upper part of the hopper is provided with a sub-hopper feed port 11, and the bottom is provided with a sub-hopper discharge port 12. Below the sub-hopper discharge port in the mixing box, a cylinder assembly box 14, a weighing hopper 15 and a mixing hopper 17 are sequentially installed. A plurality of blanking cylinders 3 are installed on the cylinder assembly box, and the connecting rod of the blanking cylinder is provided with a pull plate 13 corresponding to the discharge port of the corresponding hopper, and a weighing plate is provided under the pull plate. A device (not shown), a horizontal screw 16 driven to rotate by a motor 10 is installed in the mixing hopper, a timer (not shown) and a discharge valve 8 are installed at the discharge port of the mixing hopper, and the controllers are respectively It is electrically connected with multiple blanking cylinders, multiple weighing devices, timers, motors and discharge valves, receiving information from each weighing device, controlling the actions of the corresponding blanking cylinders, opening or closing the pull plate, and receiving the timer Information, control the motor action and open or close the discharge valve.

Schematic diagram of gravimetic blender |

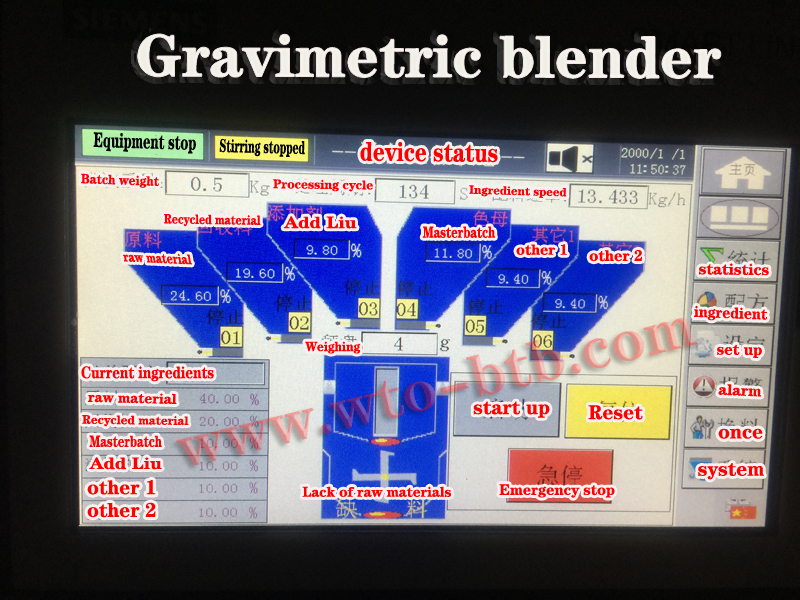

gravimetic blender console |

|

|

Further, a display 2 is installed on the mixing box, and the display is electrically connected to a plurality of weighing devices and timers.

Further, observation windows 6 are respectively provided on the plurality of the hoppers and the lower hoppers.

Due to the weighing mixer provided by the utility model, different materials are placed in different hoppers, and the corresponding weight is set by the controller according to the specified ratio in advance, and then the corresponding feeding cylinder is activated. , Make the corresponding pull plate open the discharge port of the hopper, the material will fall to the weighing device, the weighing device will transmit the information to the controller after the weight of the material reaches the set value, and the controller receives the information. Control the action of the corresponding unloading cylinder, so that the corresponding pull plate closes the discharge port of the hopper, and the material does not fall anymore, realizing automatic feeding according to the preset weight ratio, saving time and effort;

After the weighing device has finished weighing, the material falls into the mixing hopper, and the horizontal screw rotates to mix and stir the material to prevent the material from falling due to gravity, the falling speed is fast and the mixing is uneven.

A display is installed on the mixing box, and the display is electrically connected with a plurality of weighing devices and timers, and the blanking data can be directly observed from the display.

Observation windows are provided on the hopper and the lower barrel respectively, so that it is convenient to check the materials in the hopper and the lower barrel through the observation window.

The weighing mixer provided by the utility model can automatically feed materials according to the preset weight ratio and mix more evenly.

Characteristics of Gravimetic blender 1. Modular and detachable structure design, saving space and convenient cleaning;

2. It can process up to eight kinds of raw materials at the same time; the built-in suction control program can save the cost of suction control;

3. Adopt PLC controller to ensure stable and reliable performance and convenient maintenance;

4. Adopt advanced control algorithm, independent optimization, automatic adjustment compensation and vibration prevention functions to ensure the best batching accuracy;

5. Color graphic display, touch screen operation, online switching in multiple languages;

6. Weighing, volume mixing and metering mode increase the batching capacity; with formula storage function, it can store more than 100 groups of formulas at most;

7. Hierarchical security password control and alarm history record function;

8. The controller is equipped with a standard USB2.0 interface, which can save the mixing ratio data to the U disk, which is convenient for production quality control;

9. With sound and light alarms, it is convenient for the equipment personnel to quickly and accurately reach the faulty machine site.

10 All parts in contact with raw materials are made of stainless steel to prevent raw materials from being contaminated.

11. It can be directly installed on the machine or can be installed next to the machine with optional tripod.

12.The newly provided weighing mixer can automatically feed materials according to the preset weight ratio and mix more evenly. |

|

Gravimetic blender application The weight mixer is mainly used to convey powder and bulk materials for continuous conveying, dynamic measurement and control of feeding production and measurement equipment. Conveyors are widely used in the food conveying industry, pharmaceutical industry and tobacco industry. The complete machine automation device for operation calculation and batching can provide accurate measurement data and control methods for on-site management and operation. The spiral batching system is a mechatronic product integrating powder material feeding and conveying, weighing and metering and dosing control; it can be a continuous powder material batching system suitable for various industrial production environments; it adopts a variety of advanced technologies , Reliable operation and high control accuracy. When the weighing feeder is continuously unloading, it is important to ensure the weight error of the unloading. First, the material that is rotated by the screw shaft is continuously pushed forward to reach the discharge port for weighing. In order to make the weight accuracy more accurate, two pairs of screw shafts are designed (in each pair of screw shafts, one screw shaft has a large spiral length, The other spiral rib is small).

When feeding, both shafts are working and rotating. When the value read by the electronic scale is about to be close to some set value, the screw shaft with la rge diameter stops working, and the screw shaft with small diameter rotates and feeds. When the set value error is reached, how should the weighing blender make this error smaller? It is expected that a precise feeding device will be used to input the weight of the required material on the control panel, and this device can continuously convey the material Until the required value. How to ensure that the required value is reached, and then there should be an electric control device (control panel). Weigh the material while continuously conveying the material (both screw shafts are working). When the input weight value is about to be reached (the big screw shaft is suspended), the electronic weighing sensor transmits the signal to the control panel, and then The control panel analyzes the signal and suspends the power of the large screw shaft. Then use the flow rate of the small screw shaft to approximate the required weighing value (within the specified error range). rge diameter stops working, and the screw shaft with small diameter rotates and feeds. When the set value error is reached, how should the weighing blender make this error smaller? It is expected that a precise feeding device will be used to input the weight of the required material on the control panel, and this device can continuously convey the material Until the required value. How to ensure that the required value is reached, and then there should be an electric control device (control panel). Weigh the material while continuously conveying the material (both screw shafts are working). When the input weight value is about to be reached (the big screw shaft is suspended), the electronic weighing sensor transmits the signal to the control panel, and then The control panel analyzes the signal and suspends the power of the large screw shaft. Then use the flow rate of the small screw shaft to approximate the required weighing value (within the specified error range).

Weighing mixers in the food, pharmaceutical and other industries have certain accuracy requirements for the weight of each product material. Therefore, at present, with the intensification of market competition, enterprises have increasingly higher requirements for cost control. The existing production lines in these industries use balances to manually weigh the materials. The labor intensity is high, and the weighing of materials is inaccurate, resulting in scrapped products or waste of raw materials. Therefore, designing a precise feeding and weighing equipment can save raw materials and reduce costs for these industries. |

|

Gravimetic blender operating instructions 1. First plug in the power, then turn on the switch, the machine will start.

2. If the weighing type mixer is not in the position you need, then you must inching until the discharge port stops at the position you need.

3. Before starting the machine, check whether the electrical appliances are normal and whether the cover of the mixing cylinder is tightly closed.

4. The controller is equipped with a standard USB2.0 interface, which can save the mixing ratio data to the U disk, which is convenient for production quality control.

5. Volume mixing metering mode increases the batching capacity; it has the function of formula storage, which can store more than 100 groups of formulas at most; the function of hierarchical security code control and alarm history.

6. The machine should be cleaned after work, especially the inside of the barrel to prevent material residue.

7. Pay attention to add enough lubricating oil to the reducer (usually 30# mechanical oil) and lubricating grease in the transmission chain.

8. A maintenance should be carried out after six months of use. Replace the lubricating oil of the reducer, check whether the electrical appliances are aging, and replace the aging appliances.

9. After using for one year or a long period of time, a major maintenance should be carried out to check the gap of each part of the machine and make appropriate adjustments to keep the machine in good condition.

Data collection and reporting

A significant advantage of the weighing mixer is the ability to collect detailed information about the actual situation of the injection and extrusion process. Because each material component is measured in the process, the processor can obtain exact data on "which equipment and which task is consuming which material". But how to collect this data and make good use of it?Kana solves this problem through many standard reports generated at the machine level or collected at the factory. The standard report covers:

1. Current equipment status;

2. Active and recorded alarms;

3. Shifts and total inventory;

4. The amount of resin;

5. Orders and work reports.

The report can be generated according to the schedule or according to the specified time span, and the results can be displayed on the mixer controller, and can also be shared through U disk or Ethernet connection.

What is really interesting about this data collection function is that when you compile it into a separate database, it can perform a deeper analysis of plastic processing operations. In order to make this operation easier, the control output of all mixers can be compatible with standard Microsoft SQL databases, which facilitates enterprise-level analysis, and brings better consistency and higher performance to workshop operations effectiveness. For example, formulas can be recorded and stored centrally, and yield reports can be automatically generated; the use of resins can also be analyzed through formulas, shifts or totals to help manage inventory; for the purpose of ensuring quality, statistical analysis can be performed. Having so much data in one place opens the door to achieving higher efficiency and better process control, which was not possible with the previous generation of plastic processing technology. |

|

Gravimetic blender maintenance There are many material-related factors in the processing process. Over time, these factors may affect the consistency of the injection or extrusion process. The control and monitoring system of the weighing mixer can help detect and diagnose these Problems, the most important of which is to provide immediate feedback to the operator when a problem occurs.

In actual production, the control system continuously monitors the feeding and mixing process, and can issue alarms for the following situations:

1. Component valve failure: monitor the weight of the batch at the end of each batch to ensure stability, and automatically detect valve leakage;

2. Material flow error: monitor the flow of component materials to ensure their consistency, if there is an error, an alarm will be issued;

3. Discharge outlet failure of the sub-hopper: monitor the weight of the sub-hopper to ensure that it is completely poured out at the end of each batch.

Not only that, the control system can also inform the operator some other information, such as when the material is insufficient, when the bulk density of the material changes, and even when the pressure of the compressed air changes. When a discrepancy with the standard process is detected, the controller will provide an explanation and suggestions on the inspection content. It can also be networked for remote monitoring and diagnosis.

It is worth mentioning that another important factor in ensuring process integrity is the control of humidity. Applications with high temperature and humidity sensitivity require special attention. When the material is in the standard temperature range (below 150°F, 150°F=65.56°C), the Gravimetic blender weighs a batch of materials, mixes them, and prepares for the next feeding of the hopper. However, if the material is heated to a higher temperature (375℉, 375℉=190.56℃) to maintain the heat of the material and prevent moisture from entering, the mixer will not prepare a new batch of material unless the molding equipment has feed demand.

The easy-to-use touch screen can realize the quick setting of the blender, and automatically weigh the materials in the formula according to the order of the system to maintain the precise mixing relationship between the different components

How to achieve more accurate mixing by weighing mixer

A dry air blanket is optional to introduce dry hot air to fill the material mixing chamber. The system

Prevent the material in the mixer from rewetting. |

|

+8613669807274

+8613669807274

+8613669807274

+8613669807274 wto-btb@wto-btb.com

wto-btb@wto-btb.com Tel: +8613669807274

Tel: +8613669807274 SMS: +8613669807274

SMS: +8613669807274